Bullet-Proof Metal Foam As Effective As Steel At Half The Weight

Researchers at NC State have announced a breakthrough in vehicle armor that might one day help protect our military personnel and law enforcement around the world. The researchers have demonstrated new vehicle armor that is made up of a composite metal foam (CMF) and can stop .50 caliber rounds in both ball and armor-piercing varieties. The big benefit of CMF armor compared to traditional steel armor is weight savings.

The researchers say that the CMF armor is less than half the weight of steel armor. The massive weight savings could allow vehicle designers to develop lighter military vehicles without sacrificing safety or improve protection while not making the vehicles heavier. CMF is a foam that is made of hollow, metallic spheres that are made of stainless steel or titanium that is embedded in a metallic matrix made of steel, titanium, aluminum, or other metallic alloys.

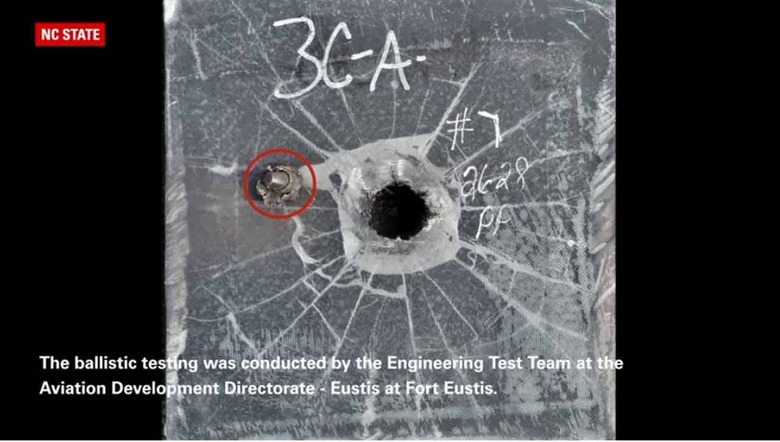

In their research, the armor used steel-steel CMF, meaning that both spheres in the matrix were made of steel. The team made a hard armor system that included a ceramic faceplate, CMF core, and a thin backplate of aluminum. In testing the .50 caliber ball and armor piercing rounds were fired at the armor at velocities of 500 meters per second up to 885 meters per seconds.

The CMF layer absorbed 72-75% of the kinetic energy of the ball around and 68% to 78% of the armor piercing rounds. The team notes that the CMF armor was less than half the weight of the rolled homogeneous steel armor needed to reach the same levels of protection.

The massive weight savings possible with the new armor will help to improve vehicle performance and fuel efficiency. Additional work is needed with the armor to enhance the material. The team says that it would optimize the adhesion and thickness of the ceramic, CMF, and aluminum layers leading to less weight and better performance for the final armor.