3D Printed Food Preserves The Nutrition And Flavor Of Fresh And Frozen Vegetables

Researchers at Nanyang Technological University, Singapore (NTU Singapore), Singapore University of Technology and Design (SUTD), and Khoo Teck Puat Hospital (KTPH) have collaborated on a new way to create "food inks" using fresh and frozen vegetables. The researchers say that the food inks preserve the nutrition and flavor of fresh and frozen vegetables better than existing methods.

A food ink is typically made from puréed foods in a liquid or semi-solid form that is 3D printed by extrusion from a nozzle and assembled layer by layer. Often in a medical setting, puréed foods are served to those suffering from issues with swallowing. In the healthcare setting, silicone molds are often used to shape puréed foods to make the food look more appetizing to those eating it.

3D printing the food allows it to be produced in a desired shape and texture in a shorter length of time. Currently, dehydrated food and freeze-dried powders are used as food inks and typically contain a high percentage of food additives like hydrocolloids (HCs) to stabilize the ink and lead to a smoother printing process. The catch is that high concentrations of HCs typically change the taste, texture, and aroma of printed food, making it unpalatable.

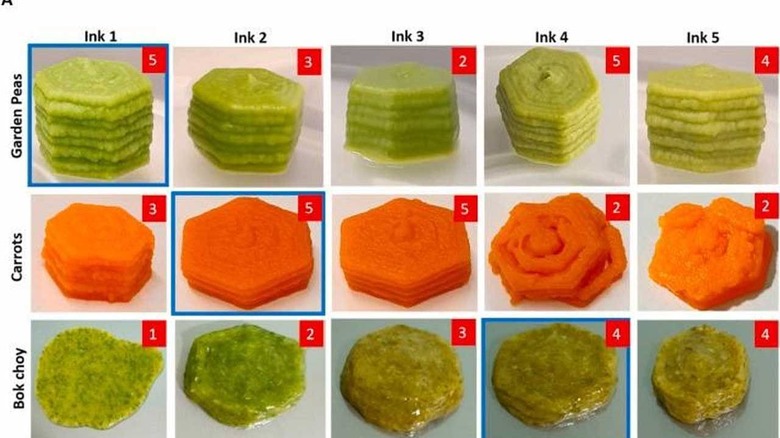

The researchers have explored combinations of fresh and frozen vegetables for making food inks stable. This allowed them to better preserve the nutrition of the printed food and make it taste better. The hope is that making food inks will lead to increased consumption by patients and improve their physical and mental health. Researchers on the project classified vegetables broadly into three categories, and each category required a different hydrocolloid treatment to become printable.

The researchers used garden pea, carrots, and bok choy as representatives for each category in the project. These vegetables required no HC, one type of HC, and two types of HCs, respectively.