This Simple Tank Modification Changed Tank Design Forever

Every now and again, an ingenious design appears in the timeline of progressing technology and forever impacts its evolution. This phenomenon happened with World War II tanks when some adopted sloped or angled armor. At the time, it seemed to be a relatively simple, presumably inconsequential design choice, but sloped armor would turn out to save many lives and change the face of warfare forever.

In the spring of 1941, German soldiers encountered T-34 Soviet tanks for the first time. These armored vehicles appeared to be impervious to shells, and everything they threw at them simply bounced off. It was so bad that Germans prioritized replacing the current Panzer IV tanks with a successor to combat the superior T-34.

While there are many other factors that make an effective armored vehicle, such as mobility and firepower, an effective tank must be well-armored without compromising all the other key characteristics — as the T-34 did. This is where sloped armor would shine. At the time, it was a genius way to deflect and deform armor-piercing rounds without needing heavy slabs of armor that would slow down the tank.

What exactly is sloped armor?

As you might have figured out by now, sloped armor is essentially an armor plate designed to face at an angle instead of standing straight (90 degrees). Therefore, when a projectile impacts and enters through the surface, it travels a longer distance through the armor plate than when it is straight.

For better visualization, when an anti-tank round is fired, it typically travels in a straight line, using its mass and kinetic energy to pierce through armor. If it met a flat armor plate 30mm thick, it would have to travel only 30mm to penetrate. However, if that armor plate were angled at 60 degrees, it would have to travel 60mm to pierce it. Meaning that the armor thickness is effectively doubled without having double the weight.

All of this is assuming that the projectile made it through the surface of the armor plate in the first place. It's easier for anti-tank projectiles to penetrate vertical plates because they can transfer all the energy to the plate and mount enough pressure to break in. On the other hand, projectiles only transfer a portion of the projectile's force onto a sloped plate, allowing deflection to happen.

A brief history of sloped armor on tanks

Sloped armor as a defensive concept is quite old. It's a design that has carried through conflicts in crafting everything from ships to other vehicles. The idea is to dissipate the projectile's kinetic energy so its full force can't concentrate on a single point.

As old as it is, strategically angled armor didn't get to tanks until WWII. The tanks of WWI primarily featured riveted steel plates capable of defending against the firepower at the time. However, the tank domination didn't last long; warring military forces researched and built armor-piercing and anti-tank guns designed to dig into the armor and cause devastating damage. In turn, the tanks of WWII upgraded to bigger and thicker welded armor.

The problem with thicker plates was that they made the tanks heavier, sluggish, more expensive and time-consuming to produce. Angled plates solved the problem because you could achieve more protection from the same plate size by setting it at an angle.

What tank was the first to feature sloped armor?

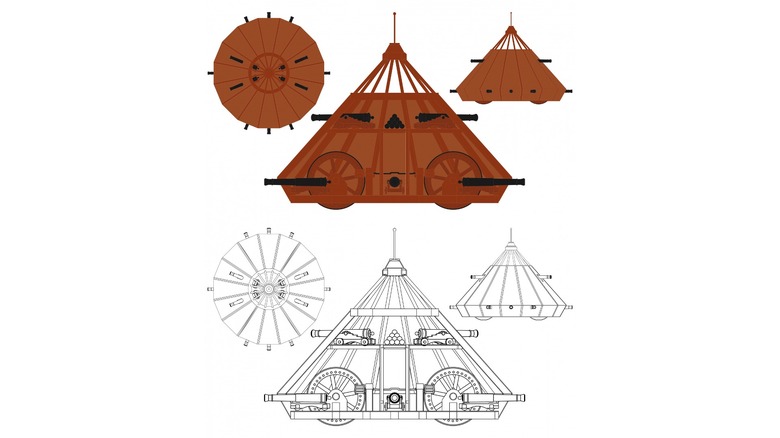

Interestingly, the first tank theorized with sloped armor was created by Leonardo da Vinci. He designed an armored "fighting vehicle" with a sloped protective cover devised for deflecting enemy fire. The tank was never built, though, meaning that the Schneider CA1 of 1917 takes the prize as the first modern tank to feature sloped armor on its hull. However, this tank and its successor, the Saint-Chamond, suffered many design issues, placing them among the worst tanks in WWI. These tanks' sloped and trapezoidal shape was more of a product of the overall shape and design requirements than intentional armor design.

The sloped design also made its way to armored cars, like the Russian Mgebrov-Renault. They didn't have the same thick armor plates as tanks, but it's proof that, by 1915, Soviet inventors were intentionally researching the effects of sloped armor and applying it to war vehicles. Another of such standout example was the German Sd.Kfz.231, which featured a fully sloped armored bodywork. But by the time this was rolling for engagement, WWII was underway, and medium to heavy tanks with sloped armor began to appear on the battlefield.

Why don't all tanks have sloped armor?

In today's wars, sloped-armor tanks have become rather obsolete because we have developed the weapons technology to nullify their advantage. For instance, long-rod penetrators with blunter noses were able to bend and warp upon impact and cut a shorter path through sloped armor. In fact, the sheer power of today's anti-tank guide missiles could easily overmatch sloped armor. You might still find sloped armor on tanks, but it's more for a holistic approach to tank design than a key advantage.

On top of that, we now have different types of armor that offer greater defense than just sloping steel plates. Reactive armor and composite armor, for instance, can offer greater protection per weight than regular armor. They are designed to meet today's projectile threats.

Back when sloped armor was apparently a major advantage for armored vehicles, some militaries, like the Germans, refused to use them — even though they were quite aware of its potency. The truth is that sloped armor has its drawbacks. For starters, sloping armor plates at an angle meant that you would have to use more material to achieve the same vertical height a regularly placed armor plate would have. So this could cause tanks to be heavier or compromise the interior comfort in a bid to find space.