Tesla Ventilators Are Made From Model 3 Parts

In addition to testing kits and protective equipment, one of the pieces of equipment that is suddenly in short supply around the world is ventilators. These machines are critical in helping those already severely infected by the COVID-19 virus breathe and fight for their lives but their shortage is costing lives daily. Companies are now scrambling to try to fill in the need and carmakers like Tesla are doing so using the materials that they already have at hand: lots and lots of car parts.

The two aren't directly connected but a lot of the mechanics and engineering that goes into making a car can also be applied to making a respiratory assistance device. From motors to air filtering and processing, car engineers and designers have some knowledge, tools, and supplies at their disposal to hastily whip up a ventilator.

Using car parts also has other practical advantages. As Tesla explains, it allows them to make these ventilators without in any way touching or taking away from the already short supply of medical equipment. It probably doesn't hurt that it also proves the company's engineering prowess, agile response, and, of course, quality parts.

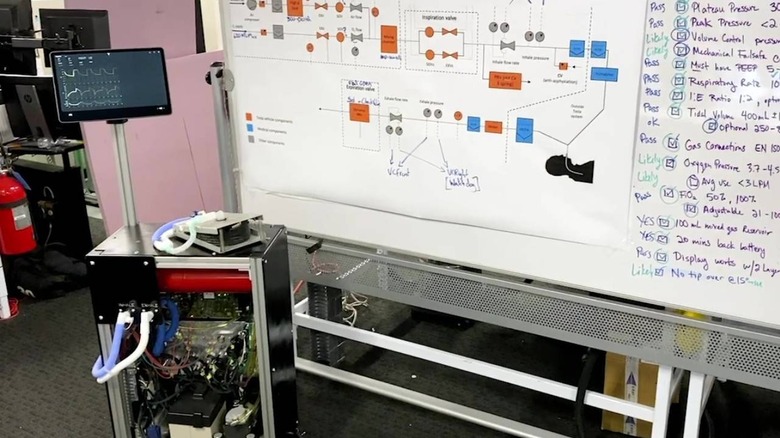

The prototype that Tesla's engineering department showed off is a mix of hospital-grade equipment that pumps oxygen in and car parts that mix it with air and regulate its delivery to the patient. Driving the whole system is a mish-mash of Tesla Model 3 parts, including a motherboard and the touch screen infotainment system.

There is no official word yet on when Tesla will be done with its ventilator but it isn't the only one rising up to the challenged. Ford and GE have also been tapped to quickly develop and manufacture ventilators to make up for the global shortage that is resulting in the non-stop rise of casualties.