NASA To 3D Print Sensors, Wireless Circuit On A Single Silicon

3D printing has been a real game changer in the modern world. It has made it possible to fabricate all kinds of objects without being subject to the mercy of large production lines. One can even 3D print food to some extent. Now researchers funded by NASA will apply that technology and manufacturing approach to print sensors and even a partial circuitry for wireless communication on a single board that's no larger than your phone.

Multisensor platforms used by scientists both on earth and in space are traditionally made like any piece of electronics today. Each of the different kinds of sensors are built separately and then integrated with other components on the board. The process is not only painstaking but also introduces opportunities for errors somewhere along the assembly line.

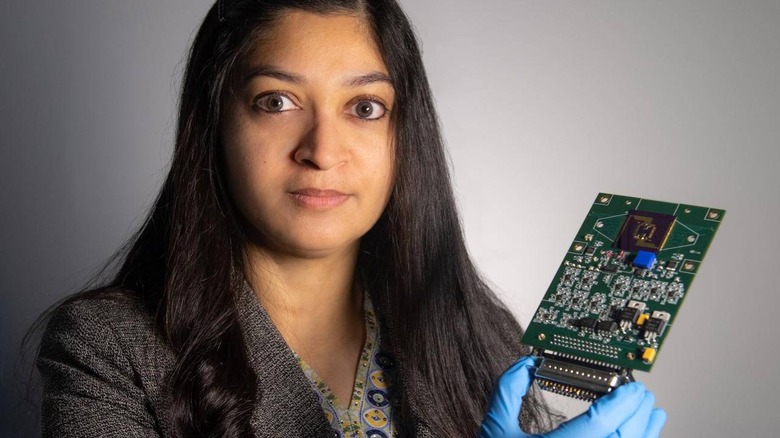

The 3D printing technology that Mahmooda Sultana and her team at NASA's Goddard Space Flight Center are working on will simplify both the production and the packaging of these essential platforms. Using nanomaterials, like carbon nanotubes, graphene, etc., they will print all the necessary sensors on the same substrate all in a single process. They might even be able to 3D print a part of the wireless communication circuitry needed for the platform to communicate the data to ground controllers.

If Sultana and her team are successful, they could change the face of NASA research forever. Each platform will be self-contained and will be able to detect all kinds of environmental data, from concentrations of gases to atmospheric pressure to temperature and communicate that data on its own. All that's needed is to add a power source and the rest of the communication circuitry.

A 3D printed multisensor platform not only simplifies the production process, it can also reduce power consumption and size of the resulting chip. This, in turn, could not only be used on planetary rovers but even in astronaut suits to monitor health and safety.