MIT 3D Printer Can Vary Glossiness Across A Printed Surface

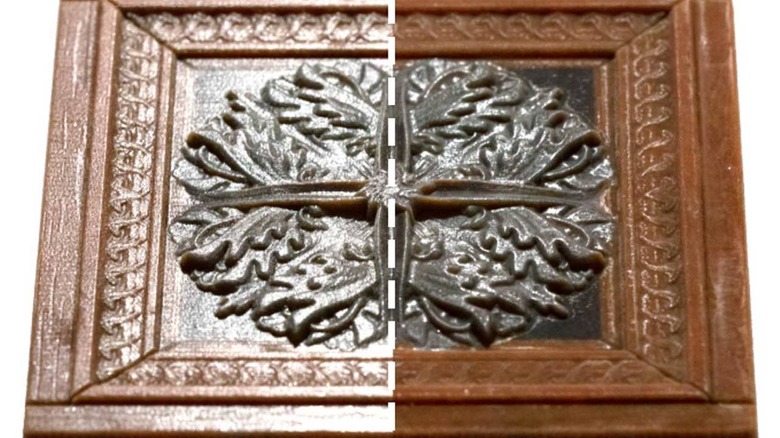

3D printers are common today, and they can produce shape and color reasonably well. While shape and color are two of an object's three most noticeable visual features, the other is gloss. Current 3D printers don't do well with changing the glossiness of the surface. MIT says glossiness is difficult because 3D printing hardware is designed to deal with different viscosities of varnishes required to give a surface a glossy or matte look.MIT researchers believe they have found the solution to that problem with a new combined hardware and software printing system. The printing system uses off-the-shelf varnishes to finish objects with the realistic, especially varying gloss pattern. Researchers foresee a range of technology applications, including reproducing fine art without having access to the originals. The team also believes that the tech could help create more realistic prosthetics.

Glossiness is a measurement of how much light is reflected by a surface. High-gloss surfaces reflect like a mirror, while low gloss surfaces, like concrete, are unreflective. Varnishes producing a glossy finish are less viscous and tend to dry into a smooth surface. Varnishes that provide low gloss matte finishes tend to be more viscous with viscosity closer to honey than water.

Matte finish furnishes tend to have large polymers that protrude randomly from the surface and absorb light when dried. Those polymers are what cause problems with 3D printers that have skinny fluid channels and nozzles not billed for something as thick as honey. Researchers say those channels are very small and are easily clogged.

The new printer the team design has large nozzles that can deposit varnish droplets of varying sizes. Varnishes are stored in a pressurized reservoir, and a needle valve opens and closes to release varnished droplets onto the printing surface. Droplet size is variable by controlling reservoir pressure and the needle valve's speed. Varying glossiness across the surface is achieved via halftoning. The printer operates with a trio of off-the-shelf varnishes, including one that is glossy, one that is matte, and one that's in between.