Engineers Create The First Manufactured Non-Cuttable Material

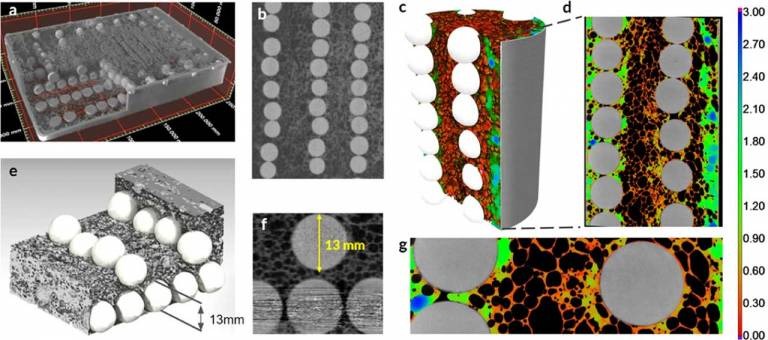

Researchers from Durham University have created what they say is the first manufactured non-cuttable material. The material is inspired by nature, and the team got the idea for the material from the tough cellular skin of the grapefruit and the fracture-resistant shells of the abalone sea creature. The material created by the researchers is called Proteus, and they say it could be used in security and health and safety industries.Proteus is made from alumina ceramic spheres encased in a cellular aluminum, metallic foam structure, and works by turning back the force of the cutting tool itself. In testing, the Proteus material could not be cut by angle grinders, drills, or high-pressure water jets. When people attempted to cut material with an angle grinder or drill, the interlocking vibrational connection created by the ceramic spheres inside the casing blunts the cutting disk or drill bit.

The ceramics are also able to fragment into fine particles filling the cellular structure of the material and hardening as the speed of the cutting tool increases. The researchers say the material is essentially like cutting through a jelly, filled with nuggets. They say if you're able to get through the jelly, you hit the nuggets, and the material vibrates in a way that destroys the cutting disk or drill bit.

The waterjet cutting tool is ineffective because the curved surfaces of the ceramic spheres widen the jet to substantially reduce its speed and weaken the cutting capacity. Researchers believe that the Proteus material could be used for all manner of products, including bike locks. It could also be used to create lightweight armor and protective equipment for people who work with cutting tools.

The researchers point out the material has only 15% of the density of steel. It's unclear when the new material might be used for commercial applications.