3D Printed Robot Requires No Assembly, Also Has Liquid Parts

DIY robots are nothing new. 3D printing parts is also nothing new. The combination of the two is also not unheard of. And yet even simple yet substantially functional robots are still in short supply today, despite advancements in the understanding of robotics or the accessibility of manufacturing methods. The problem is that event trivial robots need to be assembled, and that in itself is already quite an undertaking. MIT researchers, however, may have come upon an alternative: 3D printing a complete robot as a whole, no assembly required.

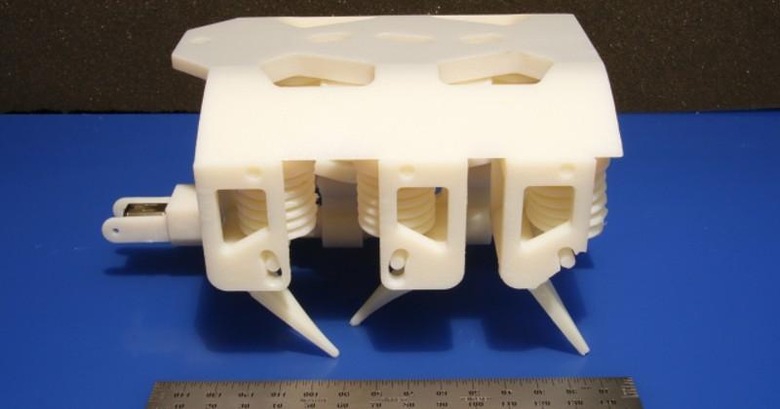

It is, of course, possible to 3D print complex structures as a whole but robots are a special case. More than anything else, they require moving parts, which are tricky to 3D print in one fell swoop. The researchers solved this problem by utilizing a hydraulic system that could be directly 3D printed without assembly. The hexapod robot used to demonstrate this has a set of bellows 3D printed inside it, translating fluid pressure into mechanical force.

However, that solution brings its own new problem, that of printing liquids. It might sound weird. even paradoxical, but being able to 3D print liquids has been one of the holy grails of this nascent manufacturing technology. While it is certainly possible, current methods required post-printing processes to be applied, like melting solid 3D printed material into liquid. That would negate the goal of having a wholly 3D printed robot with no assembly needed after printing.

The MIT researchers resorted to a tried and tested inkjet printing method with some twists of their own. They use a multi-material printing method that is commonly regarded to be complex and difficult to pull off. Some materials, like photopolymer, are solidified when treated with high-intensity UV light. Non-curing materials, on the other hand, are used for the liquid parts.

This results in a robot that can be 3D printed in around 22 hours, requires no assembly, and practically has no electronics. It does require a battery and a DC motor, the latter for turning a crankshaft that pumps the liquids into the robots legs. 22 hours though short considering the complexity, still isn't ideal. Shortening that time, however, will ultimately depend on making 3D printers print faster.

SOURCE: MIT News