10 Tools You Never Use And Can Probably Get Rid Of

We may receive a commission on purchases made from links.

Tool collections rarely stop growing. This can be especially true for people who like estate and garage sales or inherited an older relative's collection. There always seems to be another useful tool you can use to fix or build something. But while the drive to accumulate an ever-expanding variety of tools is both real and understandable, there are probably quite a few tools that many of us don't need or could stand to get rid of.

For every garage or workshop that could use a little spring cleaning, we've put together a list of some of the biggest wastes of space you may be better off without. High on that list are the tools you may still have around but really shouldn't: the dangerous ones that should probably never have been made. Also up there are some that just do a shoddy job compared to a far better tool.

Here are 10 tools that you likely never use and can probably get rid of. For various reasons, they don't belong in anybody's garage, toolbox, or life in general.

Radial Arm Saw

There was a time when this tool was common in home workshops. As time went passed and the inherent danger became more apparent, these have since fallen out of favor. Radial arm saws have been steadily disappearing for several decades now, and the reasons are manifold.

First, the radial arm saw is rarely the best tool. While it was advertised as a machine that can "do it all," most of its real use came down to crosscuts that are more effectively done with a sliding miter saw. While these excel at safely and easily making crosscuts, the radial arm saw required a cumbersome adjustment of the support column, often leaving a lot of play that resulted in inaccurate cuts.

Where the radial arm saw proves itself to be a bad idea is its variety of different angles and purposes. The blade can be tilted, tipped, and rotated to accomplish a variety of tasks, such as ripping panels and making decorative moldings. This frequently involved leaving the blade dangerously exposed. Many of the radial arm saw's purported uses just shouldn't be attempted, and are done far better (and safer) with newer, purpose-built tools.

The biggest manufacturer of radial arm saws recalled many models several years ago due to safety issues. Lacking accuracy for the jobs it can do and scarily dangerous for others, the radial arm saw is better off consigned to history.

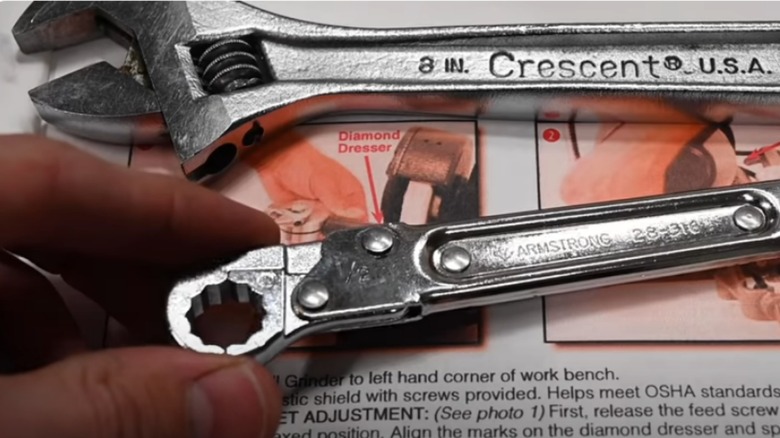

Adjustable Wrench

In theory, a wrench that adjusts to whatever nut or bolt you run into sounds like a good idea. If it's your only tool, then you can make a case that it's better than nothing. When the correct size wrench for the nut or bolt you're looking to loosen or tighten is available, however, it is always the better choice.

Adjustable wrenches, frequently called Crescent wrenches due to their original and best-known manufacturer, are prone to a lot of problems. They're big and bulky compared to a normal wrench, and most have poor ergonomics. All too often adjusting these wrenches is difficult, slippery, and time-consuming. Their potential for slipping means they're even dangerous in situations like a tight spot when you're working on a car or under the sink.

The traditional thumb dial of the traditional adjustable wrench can get sticky and be harder to use, but attempts to improve upon it have proven to be even worse. The Craftsman Mach Adjustable Wrench aims to make adjustments faster and more secure but delivers even worse performance, prone to slipping and breaking even more than the traditional one.

An adjustable wrench might be useful in a glove box or a cyclist's backpack. However, a few good wrenches of the most common sizes are a far better solution even in these situations.

Robo Grip Pliers

These pliers were introduced and got fairly big in the '90s, but peaked when people found they tended to slip under pressure. Aiming to replace channel lock pliers, the Robo Grips claimed to be able to automatically adjust to whatever you were trying to grip without ever over-tightening. While it sounds like a good idea, the reality of these laminated, spring-actuated pliers turned out to be anything but.

The teeth on Robo Grips have a reputation for being too soft, which many people have discovered as their claim to resist overtightening also turned out to be a fantasy. Most commonly, the mechanism just doesn't stand up to the repeated pressure of regular use. When this happens, the pliers don't grip at all and end up completely useless.

The exception to this may be the smaller Robo Grips, which are often the only ones many end up having after throwing out the broken, larger ones. Some users claim these are well-suited to light tasks. Though this may be the case, the full-sized Robo Grips have earned a reputation for doing a bad job of gripping things, which is the reason for owning a pair of pliers in the first place. You're much better off sticking with the tried-and-true conventional channel locks.

Universal Socket

These sockets, which carry various brand names like Gator Grip and 1-Second Socket, were touted by a flurry of late-night TV commercials years ago, and can still be found at discount outlets and forgotten at the bottom of many toolboxes. They all work similarly: a series of spring-loaded pins fit around whatever fastener they're applied to, allowing you to tighten it with a socket wrench or power drill. Think of it like a pin art toy for driving fasteners.

While the ads made these look like they were here to simultaneously replace all the world's socket sets and pliers, the reality of these tools proves otherwise. The ads never showed that you had to apply constant pressure to ensure the spring didn't force the socket off of whatever you were driving with it. Additionally, the flimsy little pins and their respective spring mechanisms were frequently too weak to stand up to the lightest uses.

Like the aforementioned adjustable wrench, this tool tries to do everything and ends up doing nothing. It grips poorly in all but a few cases, and the fact that it requires constant pressure turns many a one-handed job into a two-handed one. Many people received these as stocking stuffers and thank-you gifts, but this tool is better off in the recycle bin than in your toolbox.

Cheap Tool Kits

These kits can be found everywhere, mostly in stores where you wouldn't normally look to buy quality tools, or even tools at all. They can be found at grocery stores, in gift sections during the holidays, and even at gas stations. They have several things in common, like molded plastic cases where each tool snaps into place for convenient storage. A box of fasteners is another common accessory, and it's not uncommon to see each screw and nail counted as one of dozens of tools contained within the kit.

What these kits have most in common is low-quality tools. While reputable brands like Stanley sell higher quality versions of these things, a kit that claims to contain all the tools you need is usually a mark of a bad purchase. Many of us have received such kits as gifts or purchased them when we had no tools, only to build up a collection of better tools later on. No matter how you might obtain such a toolkit, it's probably not doing you any good unless, like the adjustable wrench, it's the only option you have.

Anything claiming to have all the tools you want is typically half useless. You're far better off buying what you need when you need it or picking up quality, mainstay tools.

(Almost) Anything with a Wooden Handle

Though wooden handles are still found on a few premium tools — especially those for woodworking –many wood handles are a sign of something whose time has come and gone.

Wood has a lot going for it. It's aesthetically pleasing, and we tend to associate it with craftsmanship. In addition to looking and feeling nice in the hand, it's relatively cheap compared to other options.

That being said, there are many drawbacks to using wood as a handle for tools. It isn't very good at absorbing vibration from impact tools like hammers. This means the shock of repeated impact gets transferred directly to your hands and arms, which, over time, can lead to injuries.

On top of its shortcomings as a shock absorber, wood also isn't the greatest at maintaining a firm grip on the things it's attached to, whether the tool head or your hands. Wood-handled axe heads and sledgehammers can slip loose over time, leading to a very dangerous situation if that heavy piece of metal comes off while you're swinging it. Coupled with the fact that wood is an organic material, prone to breaking down over time in less-than-ideal settings like basements or sheds, it probably isn't the safest material for its purpose.

A carefully maintained wooden handle can be a good thing, but many older tools simply aren't. These tools are better off being replaced or perhaps hung on the wall as a decoration.

Wobble Dado

While some of the tools on this list are questionable, this one isn't commonly available anymore. When you see it in action, it's pretty clear why.

Dado stacks–circular saw blades in a stack that cut a wide channel instead of a single blade width–are fairly common in wood shops in North America. Carefully mounted in a table saw, they can be very efficient at quickly removing a lot of material from a piece of wood, making quick work of tenons and finger joints. However, even these Dado stacks are unavailable in Europe, where the inherent danger of such a tool is considered too great a liability.

What's considerably worse than a Dado stack is the wobble Dado. This adjustable, offset blade uses a twist mechanism that makes the blade move back and forth to a varying degree, removing a lot of wood with a single blade instead of a stack of blades and chippers. The result can be dangerous, causing a saw to vibrate violently back and forth. This can be unsettling in a heavy, cabinet-making table saw, but when used in a portable job site saw, it's really not safe to use. To make matters worse, the adjustment mechanisms aren't that strong.

The wobble Dado comes from an era when safety wasn't as high a priority as it should have been, and if you have one, you should definitely get rid of it.

Cheap or Lightweight Block Planes

Bac when woodworking was dominated by hand tools like chisels and a wide variety of planes, the small block plane was a necessary part of a carpenter's tool kit. Nowadays, however, the ones you are likely to find just aren't up to much of any task, and there are better tools available for the job.

This isn't to say block planes are useless. A vintage block plane that's been meticulously maintained can be a very satisfying tool. Upmarket manufacturers still produce well-tuned examples of this hand tool. The accurate zip of a plane that leaves a glass-smooth surface, requiring little to no sanding, can be one of the best parts of woodworking.

Unfortunately, as tool manufacturing has progressed, many corners have been cut. You don't see a lot of block planes nowadays, with electric routers and sanders doing a lot of the work that the block plane used to do. The smaller block planes you encounter today are often lightweight plastic. These can be difficult to tune properly and produce far more stress than satisfaction.

The block plane has largely been superseded by more efficient power tools. Hand planes are still available, but they are usually pricey specialty items more geared toward nostalgia and aesthetics than they are to doing a job efficiently. The majority of smaller, cheaper planes have almost no use for the modern woodworker.

Magnetic Stud Finder

Electronic stud finders use vibration to detect wooden studs behind a finished gypsum wall. They do a pretty decent job at this, detecting where the resistance of solid material differs from that of hollow cavities.

At one time, tools like these came with a heavy price tag, and some excellent-quality stud finders are still fairly expensive. Finding a decent stud finder at any big-box home improvement outlet is no longer difficult. As a leftover from the days before this was the case, the magnetic stud finder is not a tool worth keeping around.

Instead of creating and reading vibrations in the surface of a wall like the vibrational ones do, magnetic stud finders work by detecting the screws used to attach drywall to studs using magnets. The flaw in this method isn't hard to spot: you have to be lucky enough to run over a screw while tediously moving the magnetic tool up and down over a wall.

With the cost of vibrational stud finders as low as they are today, the magnetic stud finder is a pointless tool to keep around. Get an inexpensive and effective stud finder for around $20 or less, and forget about the cheap magnetic ones.

Automatic Hammer

The automatic hammer rounds out this list of the most pointless tools. Nowadays, just about everyone recognizes the benefits of power tools. You probably don't have any use for a hand drill anymore, and various electric saws make a crosscut saw mostly outmoded. However, the hammer is one tool that is totally fine the way it is.

Hammers are heavy pieces of metal that we use to hit things. They commonly drive nails but can also shape metal, provide impact behind a chisel, or knock wedges in and out of place. To be clear, this is not a criticism of electric or pneumatic nailers, or of heavy jackhammers that make quick work out of demolition that was once altogether back-breaking. These tools have a practical purpose, but the automatic hammer does not.

The automatic hammer aspires to create a need where one just doesn't exist. It's a single-use tool that, held over a fastener, pounds it into a wall. To state what should be blindingly obvious, all this does is complicate the simplest of tasks. If you can hold up a power tool to a place where you'd like to put a nail, you can almost certainly hit it with a hammer.

Nailers and nail guns are one thing, but the automatic hammer is a pure gimmick. A hammer must be a heavy, flat piece of metal used to hit a nail; no electricity is needed.