MIT's artificial muscles could benefit robots and medical devices

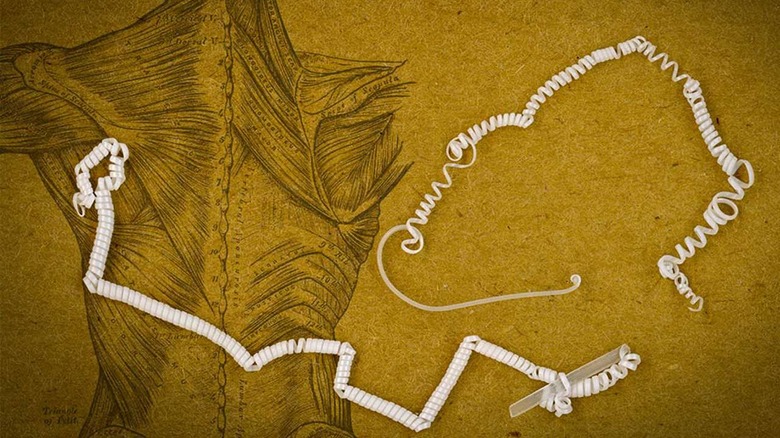

MIT has taken inspiration from the way a cucumber plant grows to create contracting fibers that imitate the coiling-and-pulling mechanisms that the cucumber plant uses to pull itself upwards to get the most sunlight. The team says that the contracting fibers could be used as artificial muscles for robots or used in prosthetic limbs or other mechanical and biomedical applications.

The new fiber-based system MIT has developed is extremely lightweight and can respond very quickly. The key to the process is mating two materials together that have very different thermal expansion coefficients. The two materials have different rates of expansion when they are heated, MIT notes this is the same principle used in many thermostats.

With two different polymers bonded together, a highly stretchable cyclic copolymer elastomer and much stiffer thermoplastic polyethylene, the team created a fiber that could be stretched to several times its length. When the scientist picked up the fiber in his hand for the first item, it naturally curled up from the warmth of his hand alone.

The team found that their fiber would coil with even small increases in temperature. When the temperature went back down, the fiber returned to its original length. The coiling and uncoiling motion produced a surprisingly strong pulling force. Later testing showed that the process of contracting and expanding could be repeated 10,000 times, and the material was still going strong.

One reason it last so long is because the process operates at moderate temperatures. Only a 1-degree Celsius increase in temperature can cause the material to start contraction. The fibers are easy to make and can be produced in batches up to hundreds of meters long. The first batch was able to lift loads up to 650 times its own weight.