MIT's 3D printed 'skin' will make more durable robots, drones

Imagine a robot or a drone that is made with a 'skin' of sorts capable of precise amounts of shock absorption, something tailored to meet the precise needs of the device. That's exactly what MIT researchers have made possible via a new shock-absorbing 3D material for robots that offers all sorts of interesting properties, not the least of which is less bouncy, more precise and controlled landings after a blow.

Think of this material as being the very thing BattleBots creators dream of. The material is soft and made with a 3D printer, and it aims to make robots and other devices fitted with it more durable. This could be robots, of course, but also other things that have to take an impact and absorb high levels of shock: helmets, for example, or smartphones.

The new 3D printing method and material, dubbed the programmable viscoelastic material, was created by MIT Computer Science and Artificial Intelligence Laboratory (CSAIL) researchers. Rather than offering just a single level of shock absorption, the new material is designed to be 'programmable,' hence the name — each 3D printed part made of it can be set to a specific level of elasticity and stiffness, equipping it to respond to shocks in specific ways.

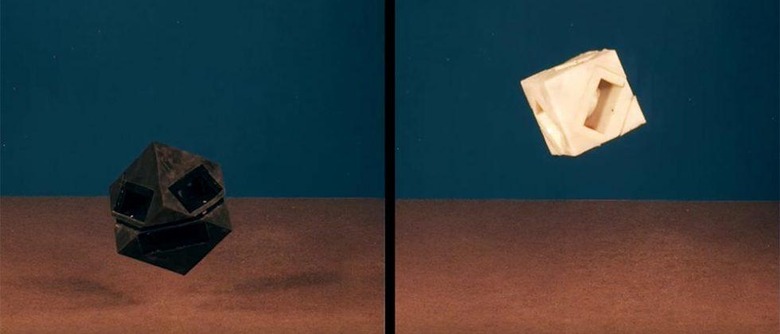

This is demonstrated by the robotic cubes shown above — one has much less bounce than the other, able to land more precisely and more quickly as a result. One obvious use for such material would be in drones, particularly delivery drones that may be carrying heavy payloads and would be at risk of breaking in the event of a crash or collision. It's not clear at this time what future plans the researchers may have for their material.

SOURCE: MIT