Human bone inspired new 3D printed material

Scientists from Cornell University, Purdue University, and Case Western Reserve University have created a new 3D printed material that has a design inspired by bone. The team says that bones and 3D-printed buildings have something in common. Both have columns and beams on the inside that determine how long they last.

The team says that the discovery of how a "beam" in human bone handles a lifetime of wear and tear could translate to the development of 3D printed lightweight materials that last long enough for more practical use in buildings, aircraft, and other structures. The team found when they mimicked the beam and made it about 30 times thicker, the artificial material could last up to 100 times longer.

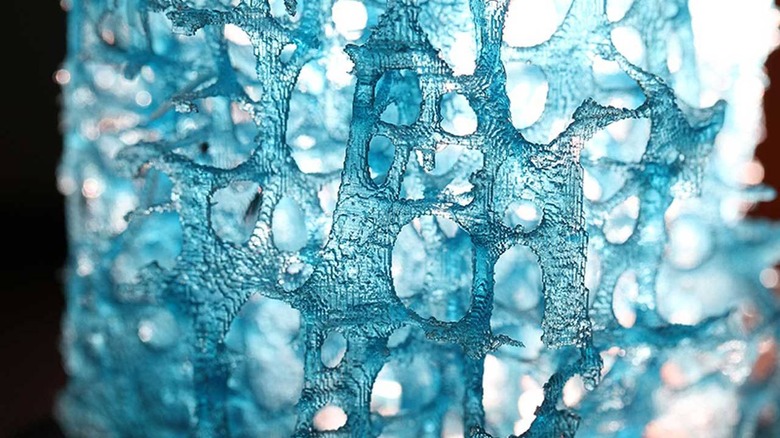

Scientist Pablo Zavattieri says that bone is a building and that it has columns that carry most of the load and beams that connect the columns. Bone gets its durability from a spongy structure called trabeculae. That is a network of interconnected vertical plate-like struts and horizontal rod-like struts that act as columns and beams. The denser the trabeculae, the more resilient the bone is for everyday activities.

The team found that in bone, the seemingly insignificant horizontal struts increase the fatigue life of the bone. The team says that the challenge of making 3D printed buildings more robust could be solved by redesigning the internal structure of the cement. The team determined that the horizontal struts might play a more significant role in human bone than previously thought; they then designed 3D printed polymers with architectures similar to trabeculae.

Applying loads to the bone-inspired 3D-printed polymers confirmed that the thicker the horizontal struts, the longer the polymer would last as it took on a load. The thicker struts didn't significantly increase the mass of the polymer leading the team to believe that the design would be useful in making lighter and more resilient materials.