Expandable foam for 3D printers can make items bigger than the printer

There are myriad of uses for 3D printers in industrial, research, and consumer applications. The catch in those applications is that the printed objects have to be smaller than the machine that makes them. When large parts are needed, larger 3D printers are required, and there is a practical limitation to how large those printers can be.

Researchers have now created a new expandable foam 3D printing material that allows printers to create smaller objects that can expand on their own to make larger objects when the printed object is heated. The foam material appears to expand like the aerosol cans of spray foam insulation homeowners may use from time to time.

The expandable foam printing material was developed by scientists from the University of California, San Diego. The team wanted to create an expandable resin usable for printing large objects with an inexpensive, commercially available 3D printer. Several different resin formulations were tested to find one that allowed the printing of an object that expanded when exposed to heat.

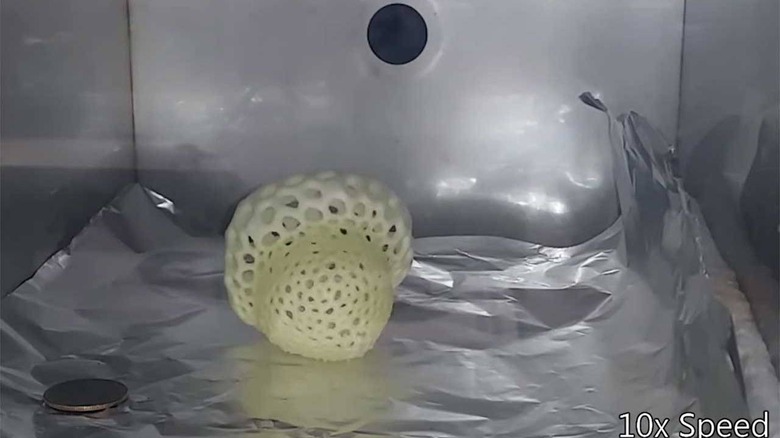

The resin formulation was used to print a hollow, latticed sphere. Heating the sphere caused a volatile component of the resin to bubble out as a gas. The result was a porous, polystyrene foam-like material up to 40 times larger in volume than the original printed object.

Researchers also able to print many other shapes, including a boat, which could carry about 20 times more weight at its expanded size. They also 3D printed a wind turbine able to produce a small amount of electricity at its larger size. The team notes that the new material isn't as strong as polystyrene foam, but it could someday be used for cushioning, airfoils, bouncy aids, or expandable habitats for astronauts.