Engineers create thin, stretchable electronic material that is gas permeable

Engineering researchers at NC State University have created an ultrathin, stretchable electronic material that is gas permeable. Being gas permeable allows the material to breathe, making it more comfortable to wear. The researchers designed the material specifically for use in biomedical or wearable technologies where gas permeability allows sweat and volatile organic compounds to evaporate away from the skin.

The breathable capability makes the wearable electronics more comfortable for users to wear over the long-term. Researchers say that gas permeability is a big advance over earlier stretchable electronics. The teams says the material they've developed is important because it's a simple process that's easy to scale up. The researchers used a technique called the breath figure method to create a stretchable polymer film featuring an even distribution of holes.

The film is coated by dipping it in a solution that contains silver nanowires, and then the material is heat pressed to seal the nanowires in place. Researchers say that the resulting film shows an excellent combination of electrical conductivity, optical transmittance, and water-vapor permeability. With the silver nanowires embedded just below the surface of the polymer, the material also has stability in the presence of sweat.

The material the team created is fragile and only a few micrometers thick. Gas permeability for wearable electronics is significant for comfort because if it's not gas permeable, skin irritation can result. The first prototype the team created was a skin-mountable, dry electrode for use as an electrophysiological sensor. Sensors of that sort have multiple potential applications, including ECG and EMG measuring.

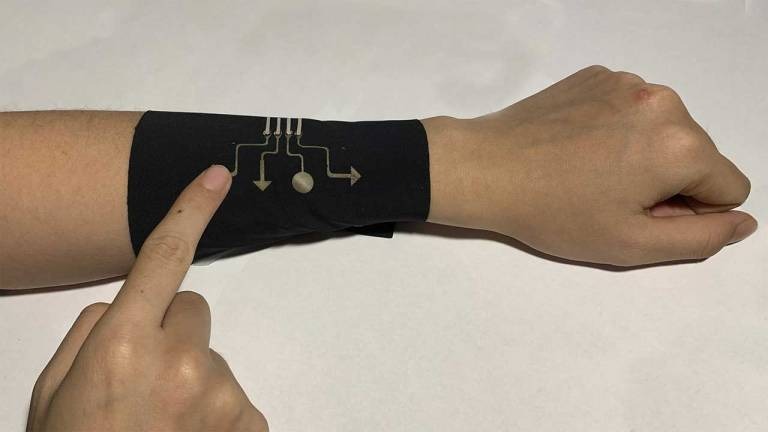

The second prototype team created was textile-integrated touch sensing for human-machine interfaces. That sleeve was used to play computer games such as Tetris. The researchers' work is being supported by the National Science Foundation.