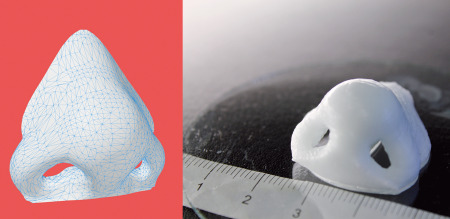

Bioprinter 3D-prints living cartilage nose in 16 minutes

While traditional 3D-printers build objects using layers of plastic, we've seem some great strides in 3D-printing like lattices emerging from amorphous, resinous goo. Now bioprinters are entering the ring with their ability to create 3D models from biological materials. There's no need to wait for an ear to grow on the back of a mouse; this bioprinter from the ETH Zurich Cartilage Engineering and Regeneration Group can print a nose from biopolymers and living cartilage cells in only 16 minutes. Best of all, no mice are harmed in the process!

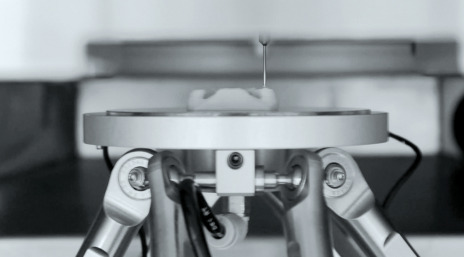

Matti Kesti is a doctoral student and the head of research behind Professor Marcy Zenobi-Wong's new 3D-bioprinter. It prints using eight syringes which can each be filled with a different suspension. This allows for different densities just like natural human tissue. In this 3D-bioprinter lies the potential to transform the field of reconstructive surgery. Not only could a new nose be printed for the victim of a vicious animal mauling, but scientists could engineer a 3D model that matches his old nose, exactly. This would give trauma patients back a small semblance of self in the aftermath of injuries.

Cartilage transplants are currently used to treat sports injuries, but doctors have been limited to inserting 2-dimensional, flat patches of laboratory-grown cartilage over the injured joints. This new 3D-printer can create cartilage designed specifically to treat an individual injury, reducing scar tissue build-up and other complications.

The bioprinter is scheduled for animal testing this year before any human trials can be conducted. Zenobi-Wong says the field of bioprinting is still a long way off from creating functional organs other than cartilage. Bioprinted cartilage acts as a base for existing capillaries, whereas other organs like a heart or lungs would need their own capillaries for blood-flow, and that research is still a long way from fruition.

VIA: Engadget