New inexpensive method turns carbon dioxide into nanofibers

Carbon emissions — the same kind of pollution that is spawning giant crabs — can be turned into carbon nanofibers using a new method said to be "potentially a lot cheaper" than current methods. Said the researcher behind it, the new method offers a "means of storing and sequestering carbon dioxide in a useful manner, a stable manner, and in a compact manner." The new method could have big implications for the environment — if renewable energy is used to power the conversion process, it will be a particularly effective way to reduce carbon pollution levels.

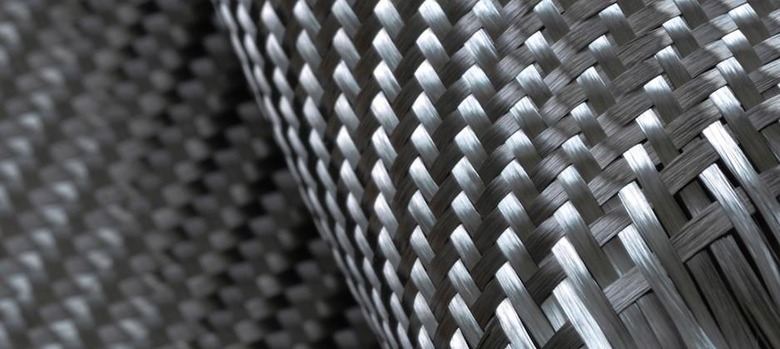

Carbon fibers are used in a variety of products and industries, including in big ones like the automotive industry, due its combination of strength and light weight. The benefits of carbon fiber increases when moved down to the nanofiber scale, but making carbon nanofibers is even more expensive than the cost to produce carbon fibers.

George Washington University's Stuart Licht, a chemistry professor, alongside a team has demonstrated their new method of carbon nanofiber creation; it involves nabbing carbon dioxide from the air and, using an unspecified electrochemical process, transforms that carbon pollution into both oxygen and carbon nanofibers. In addition to being substantially cheaper, this new process is also said to be more efficient.

The researchers were able to produce different diameters and shapes with the nanofibers by tweaking the conditions used to produce them. And while the mechanisms that produce the fibers' formations isn't fully understood yet, the researchers say they can make "very uniform fibers" using this process. As more work is done with the process, it is expected even greater control over the final product will be developed.

SOURCE: MIT Technology Review