New conductive ink for ballpoint pens can write circuits on virtually any surface

Conductive ink has been around for a while and is a tool for printing flexible electronic circuits on various surfaces. One challenge with current conductive ink is that the ink can be expensive and is incompatible with some materials. Another challenge is that the conductive inks also tend to clog up the devices used to apply them. Researchers have created a new conductive ink that can be used on virtually any surface that is applied with a clog-free ballpoint pen.

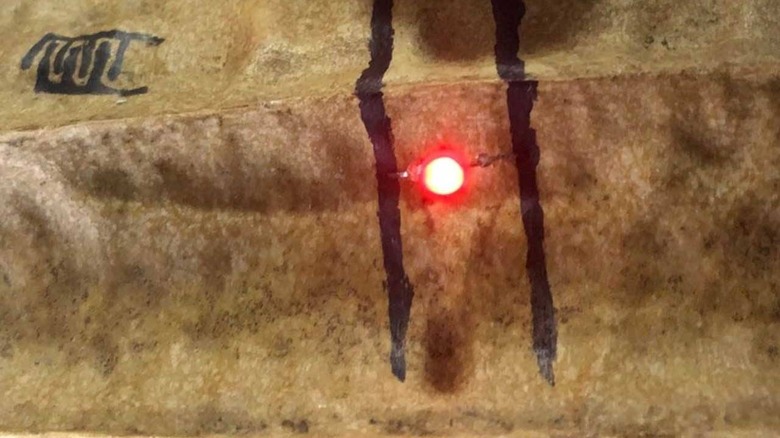

The ballpoint pens can "write" circuits almost anywhere, including human skin. Flexible electronic circuits created using the pen can be used for a range of applications, including biosensors, electronic skin, and energy storage. So Yu Liao, Jun Qian, and other researchers on the project developed the water-based ink containing conductive carbon particles made of graphene nanosheets, multiwalled carbon nanotubes, and carbon black.

A material known as maleic anhydride modified rosin resin was added to the new ink as a binder and to reduce the ink's solid content and viscosity. The team also added xanthan gum to stabilize the suspension so that the carbon wouldn't settle out of the ink.

By optimizing the viscosity and the size of the conductive particles relative to the tip of the pen, a system able to write stably and smoothly on both flat and irregular surfaces was created. Circuits drawn using the pen were able to withstand multiple cycles of folding without deterioration.

The ink was stable after sitting for 12 hours and released no harmful gases during use. The pen and ink are much cheaper than other similarly available systems. Researchers used their creation to draw flexible, wearable electronics on both soft substrates and human skin.